Precision Key Cutting Gauge

KeyGauge.com was created to easily check your key cutting machine accuracy and adjust if needed.

Here’s how it works:

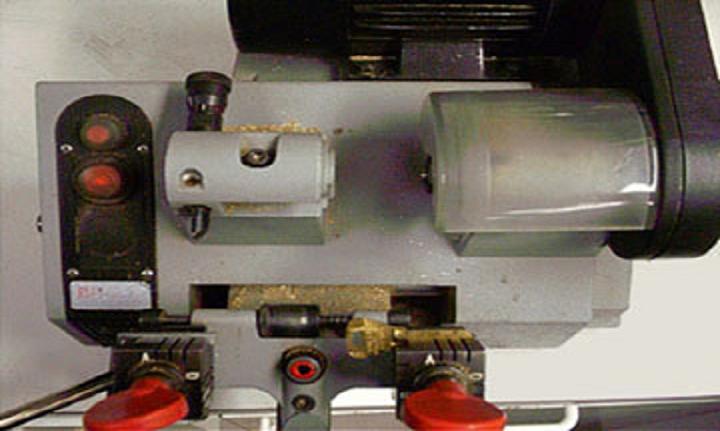

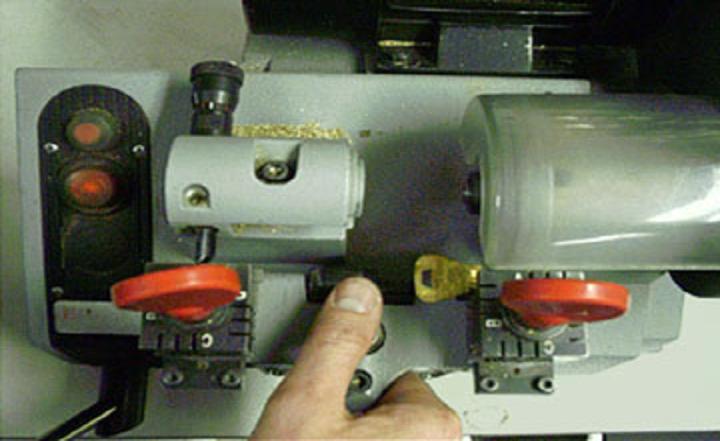

1. Place key blank in vice in front of cutter. Place KeyGauge in vice to trace. Be sure it is centered; you will need to be able to cut from bow to tip.

*KeyGauge. com recommends using a WR4 or any long, six pin blank.

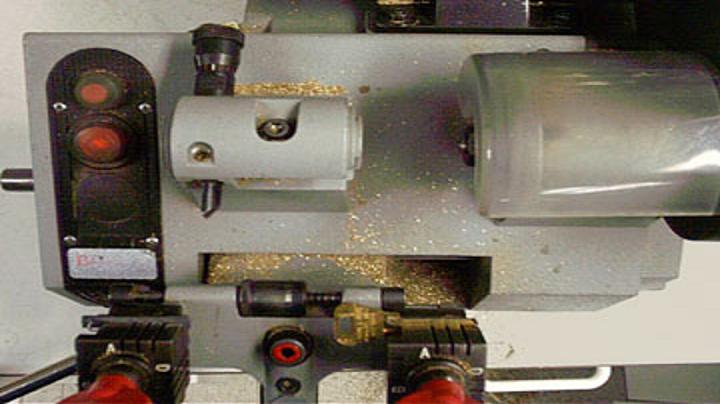

2. Cut the blank key from bow to tip tracing the KeyGauge.

3. The cut key should be flat like the KeyGauge since there are no high and low points like a regular key would have.

4. Remove key from vice and de-burr

5. Using your micrometer, measure the key on the bow, middle and tip and record the measurements.

6. All measurements should read exactly 0.250 inches.

7. If key does not read 0.250 inches your machine needs adjusting. Adjust machine per manufacturer’s instructions using steps 1-5 as needed until tolerance is within 0.001 inches.

Note: If both ends do not read the exact amount you have a taper and should be adjusted per manufacturer’s specifications. If this cannot be done make sure the middle of your vice is at .250 and this will split the difference.

Keygauge.com is a precisely machined hardened steel gauge that will allow you to easily adjust your key machine to exact specifications rather than guessing with a key micrometer. Don’t aggrivate customers by making them keys that don’t work. For the mere price of a key blank you can be sure your keys will be right on!

Recommended links to other locksmith and keycutting tool sites:

Precision Key Cutting Gauge

© KeyGauge.com